the whole world of producing is continually evolving, driven by the need for enhanced precision, efficiency, and price-usefulness. a person know-how which is swiftly transforming industries is laser welding. As a leading Laser Welding device provider, we have been witnessing firsthand the profound effect these devices are getting on modern manufacturing procedures. This blog write-up explores the core Positive aspects and benefits of laser welding, demonstrating why it has become an indispensable Device for businesses striving to stay competitive.

Table of contents:

Introduction to Laser Welding Technology

Advantages of Laser Welders more than conventional Welding techniques

How Laser Welding equipment strengthen manufacturing performance

Introduction to Laser Welding know-how

Laser welding is usually a fusion welding course of action that utilizes a concentrated laser beam to affix elements. The substantial concentration of Power permits deep, slim welds with nominal warmth-affected zones. This specific Regulate minimizes distortion and harm to bordering supplies. compared with standard welding approaches, laser welding can be utilized on a wider array of elements, like dissimilar metals, and sometimes calls for minor to no filler materials. the method is adaptable to automation, enabling for greater velocity and regularity more info in creation. The Laser Welding device supplier marketplace is growing quickly, driven because of the escalating demand from customers for this flexible know-how.

benefits of Laser Welders about Traditional Welding strategies

in contrast to standard methods like MIG or TIG welding, laser welding gives numerous critical rewards. initial, the precision of the laser beam allows noticeably smaller and even more aesthetically pleasing welds. next, the heat-impacted zone is noticeably minimized, reducing distortion and preserving the integrity from the bordering materials. Third, laser welding is considerably quicker, resulting in increased creation throughput. Fourth, it could possibly weld dissimilar metals a lot more efficiently, opening up new design and style choices. at last, laser welding is very automatable, reducing labor fees and escalating regularity. This suite of benefits makes laser welding a compelling option to regular welding strategies for the big range of programs.

How Laser Welding equipment boost output effectiveness

Laser welding considerably increases production performance in a number of means. The velocity and precision of the process let for more quickly welding cycles, leading to larger output volumes. Automation capabilities further more boost effectiveness by reducing the need for handbook intervention and minimizing faults. The slim weld seams require considerably less publish-weld ending, conserving time and means. In addition, the chance to weld dissimilar metals simplifies production processes and reduces the need for numerous becoming a member of procedures. as an example, As outlined by information from LatheGlobal, their fiber optic, h2o-cooled laser welding (HW-2000W) tools demonstrates the Innovative engineering driving this effectiveness revolution. The dependability and repeatability of laser welding contribute to reliable products excellent and reduce scrap prices, additional boosting In general efficiency.

In conclusion, laser welding is revolutionizing contemporary manufacturing by supplying unparalleled precision, speed, and effectiveness. From aerospace to automotive to electronics, industries are ever more adopting laser welding engineering to get a aggressive edge. being a Laser Welding Machine provider, we have been dedicated to giving slicing-edge remedies that empower organizations to rework their producing procedures. in the event you want to help your output capabilities and stay in advance from the curve, contemplate Discovering the advantages of laser welding. The future of manufacturing is right here, and It is staying welded with lasers.

Emilio Estevez Then & Now!

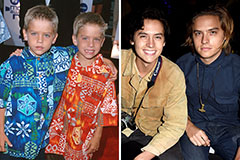

Emilio Estevez Then & Now! Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Patrick Renna Then & Now!

Patrick Renna Then & Now! Andrea Barber Then & Now!

Andrea Barber Then & Now! Keshia Knight Pulliam Then & Now!

Keshia Knight Pulliam Then & Now!